| The advantages of using plastic racks instead of metal or wooden products are obvious: |

| · Fulfil all HACCP requirements and are suitable for storage and transportation of empty and full bottles and for direct use at the bottling line |

| · As far as those are produced by primate polypropylene and suitable non toxic masterbatches are free of odour and any kind of migrational elements that could affect the quality of the bottled water |

| · Easy to keep clean, can be washed with water and standard detergents |

| · Lightweight but strong and durable, never require repairs |

| · Easier to handle from their users, can be picked up on four sides by any kind of fork-lift |

| · Safer as there are no splinters or sharp edges that could injure users or scratch the bottles |

| · Impervious to acids, fats and solvents, neutral to odors and tastes and fully insect and fungus-resistant |

| · Suitable for any automated bottling line as the material does not deform and the dimensions of the rack are standard and precise |

| · Can be supplied in specific colors or with logo on the 2 sides |

| · Can be stored outside as do not absorb water and contain UV supplement to protect those against UV radiation |

| · Broken or old racks can be recycled and used in percentage for the production of new racks or other plastic products (LAMAPLAST has already the equipment and the experience to utilize those) |

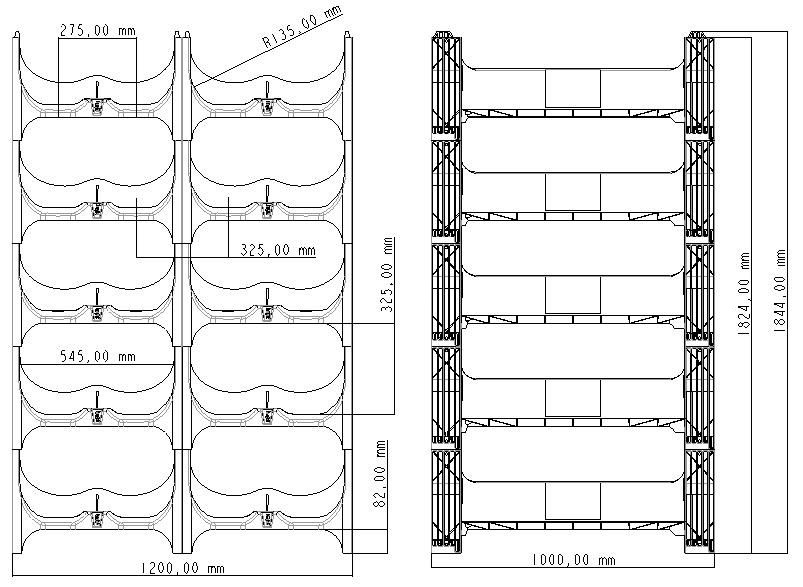

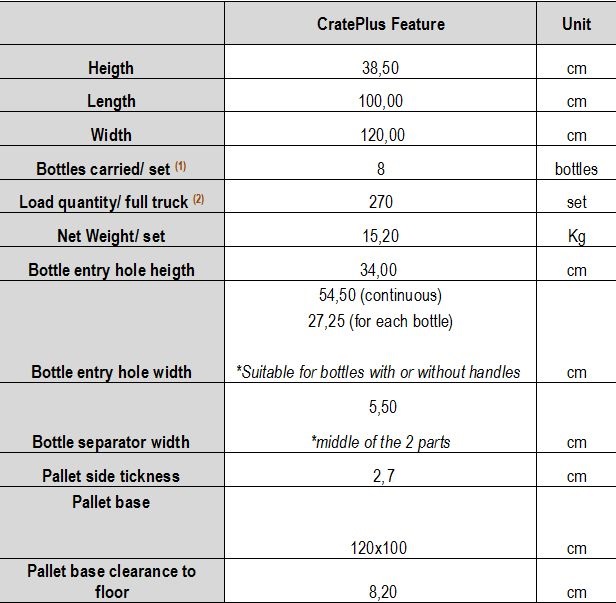

| This new product is compatible to most of the plastic crates that are already used as their shape, size and dimensions are the same. Their geometry and their matching points are also the same for easy stacking and mounting among those racks and other existing plastic crates. |

| Having more than 40 years of experience in designing and construction of moulds and producing of plastic products by injection molding we managed to design and produce a plastic rack that has all the advantages of the existing plastic crates. Moreover due to its special design is much more durable and ergonomic. |

| In order to be sure about it we have discussed a lot with bottlers and distributors that are already using the existing plastic crates and we have examined very carefully their remarks about limited strength of those as well as their propositions about the possible improvements. |

| We have performed a lot of tests in order to find out the weak areas and the reasons that could break those. |

| Taking into account their propositions and the results of our tests we have designed carefully those areas in order to make them as strong and durable as possible. Thus: |

| According to the results of our tests (and our experience), limited strength could be caused due to the use of low quality recycled. This material can’t fill the mould properly, resulting in bubbles formation inside the ribs and consequently in limited strength and easy breakage at those areas. |

| Additionally, this material is too rigid, can’t absorb any kind of vibrations during handling or transportation and brakes rather easy. |

| We have also performed the trial tests with several types of Polypropylene. The most suitable material is a compound of primate homopolymer and copolymer of food approved Polypropylene, which is soft but strong and durable, fills the mould uniformly and absorbs part of the vibrations that could cause breakage of the rack. This material is smoother than Polycarbonate and helps to avoid scratching of the bottles. |

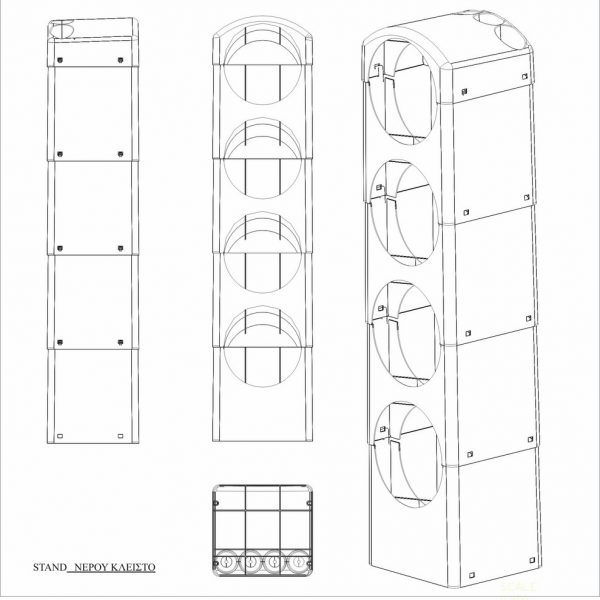

| According to their remarks and the results of our tests, the areas around the feet are the most problematic and had to be strong enough. The improper handling (trailed on the floor or stricken by the forks of the fork-lift) could cause a lot of problems (breakages). Our racks have totally 24 ribs more around the four “foots” of it (see pictures 2 & 3), increasing significantly the strength and the useful life of it. |

| We have designed carefully all the injection points and the material transfer lines inside the mould for faster and more uniform filling of it. Due to this, we succeeded also to decrease the weight of the rack by almost 10% and to avoid any bubbles formation. |

| The bottom part of the rack was designed for easier and safer handling. |

| The design of the bottom part ensures that the forks of the fork-lift can be placed without injuring or breaking the feet (where 80% of the damages were found). In order to secure it, the ribs at the left and right side of the bottom (coloured in red and blue) are bigger than those at the centre, leaving a free space of ~70cm where the forks should be placed. |

| Placing the forks inside this free space helps also the user to balance the load easier and handle it with safety. |

| The areas at the bottom of the rack where the forks should be placed are flat and big enough and at the same height as the rest of it (see picture 2 & 3). The rack lay smoothly on the forks and is more stable during handling with the fork-lift. |

| A metal plate can be placed at the bottom of the feet to protect them from deforming during handling (trailing on the floor), keep their original shape and stack one on the other without problems. |